Space-Qualified Optical Filters

In the unforgiving environment of space, the reliability and precision of optical components can determine mission success. At Andover Corporation, we understand the challenges faced by space agencies, contractors, and program managers. Our space-qualified optical filters, windows, and components are built to meet the highest standards of performance and durability.

Meeting the Challenges of Space

Space exploration subjects materials to extreme conditions that test the limits of engineering. Optical filters and windows used in space must endure rapid temperature shifts, intense radiation, and the stresses of launch and microgravity. Andover Corporation’s products are designed with these factors in mind.

Our optical filters and windows maintain exceptional thermal stability from −100 °C to +100 °C and beyond, preserving system integrity under harsh thermal cycling. Radiation-hardened materials resist cosmic and solar radiation damage, ensuring consistent optical performance over long-duration missions.

Superior Optical Performance

Andover’s coatings deliver high transmission in the target wavelength range with minimal reflectance, enabling clear and accurate data collection for both Earth-observing satellites and deep-space telescopes. Precision tolerances for thickness and flatness ensure reliable, repeatable results even in microgravity conditions.

Advanced Materials and Coatings

Our space-qualified filters and windows are fabricated from high-purity materials including fused silica, BK7, and chalcogenide glass. These substrates combine strength and optical clarity. Chalcogenides are particularly valuable for infrared applications, offering low weight and excellent IR transmission. Multilayer dielectric coatings and protective layers are applied to maximize durability in vacuum and radiation environments.

Rigorous Testing and Quality Assurance

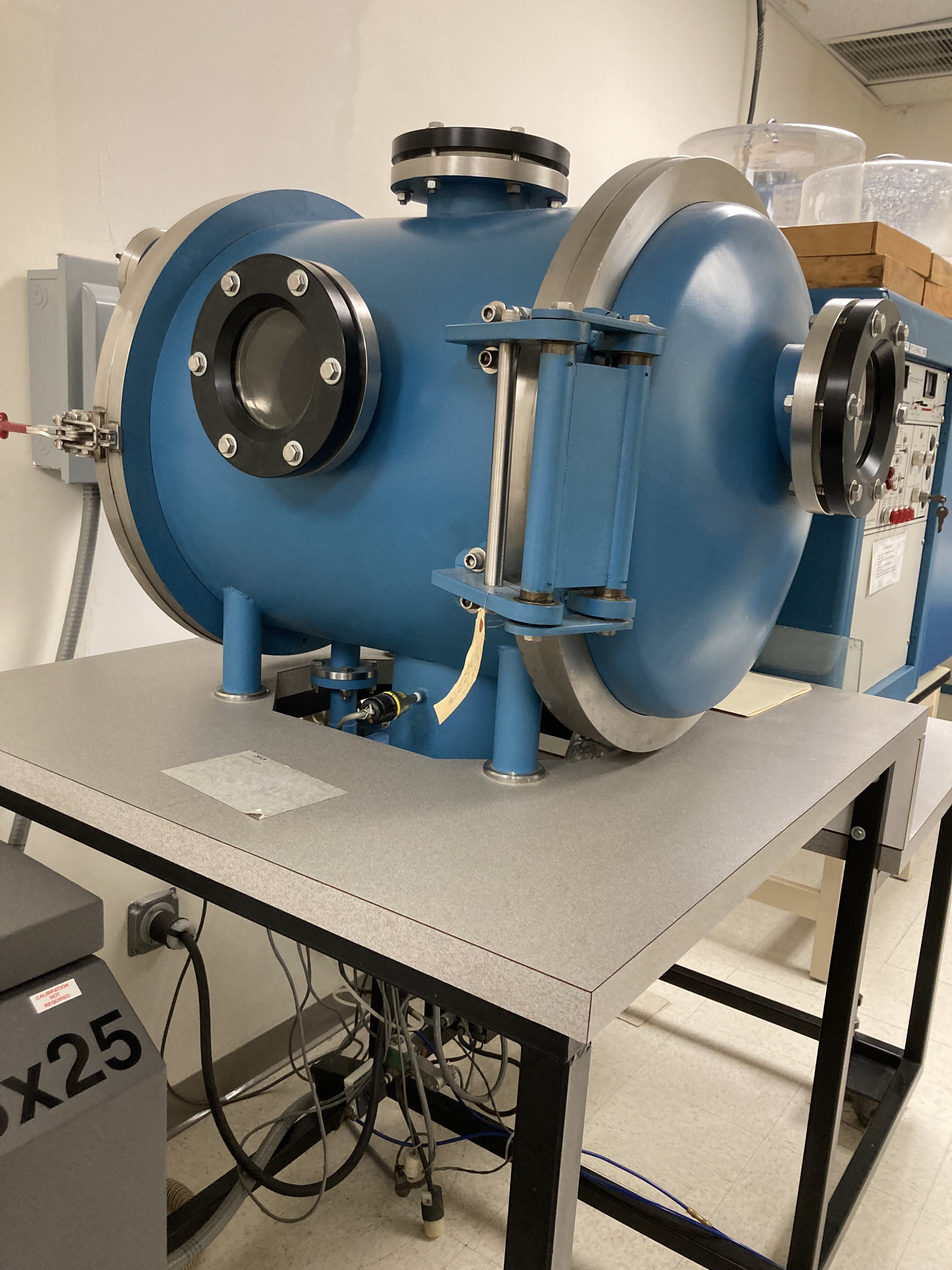

Every product undergoes extensive qualification testing to meet aerospace and military specifications. Broadband and narrowband spectral characteristics are verified using advanced spectrophotometry, while custom interferometers measure transmitted wavefronts to confirm optical accuracy.

Our environmental test chambers replicate space-like conditions ranging from −62 °C to over 500 °C, ensuring that coatings remain stable through repeated temperature cycles. Each glass component is inspected for striae, inclusions, and bubbles, ensuring the highest optical purity and reliability.

Applications in Space Exploration

Andover’s space-qualified filters and windows are integral to many space missions. For Earth observation satellites, multispectral and hyperspectral filters support critical research on climate, land use, and ocean dynamics. In communication satellites, our optical windows enable advanced laser transmission systems.

Our products have supported numerous flagship missions, including the Hubble Space Telescope, which continues to deliver groundbreaking imagery from low Earth orbit. We also contributed optical components to the Helioseismic and Magnetic Imager (HMI) launched in 2010, enabling detailed solar research.

Our filters are used in visible, ultraviolet, and infrared astronomy applications. The Stratospheric Observatory for Infrared Astronomy (SOFIA) relied on our infrared filters to investigate celestial magnetic fields and star-forming regions, including the 2020 discovery of water on the Moon.

Specialized filters for solar observation—used in missions like the Interface Region Imaging Spectrograph (IRIS) and Solar Diameter Imager and Surface Mapper (SODISM) on the PICARD satellite—enable precise solar irradiance and structural measurements. Other projects such as MatISSE and the MiRaTA CubeSat demonstrate our ability to deliver advanced optics for both large and compact satellite systems.

Commitment to Excellence

Andover Corporation’s vertically integrated processes ensure unmatched consistency and responsiveness. From design to fabrication and metrology, we maintain full control of every step, enabling fast lead times and custom craftsmanship. With no minimum order requirements, we accommodate missions of any scale while delivering the quality demanded by space programs worldwide.

Conclusion

As exploration expands beyond Earth, the need for dependable, high-performance optics continues to grow. Andover Corporation’s space-qualified optical filters and windows provide the precision, durability, and trust required for mission success. Contact us today to learn how we can support your next space initiative.

Andover Insights & Innovations

Discovering new possibilities in optical filtering

Optical Filters in LiDAR and Laser Technology

Contact Our Team

Ready to discuss your optical needs? Whether you're looking for a quote or have technical questions, our expert team is here to help guide you to the perfect solution.